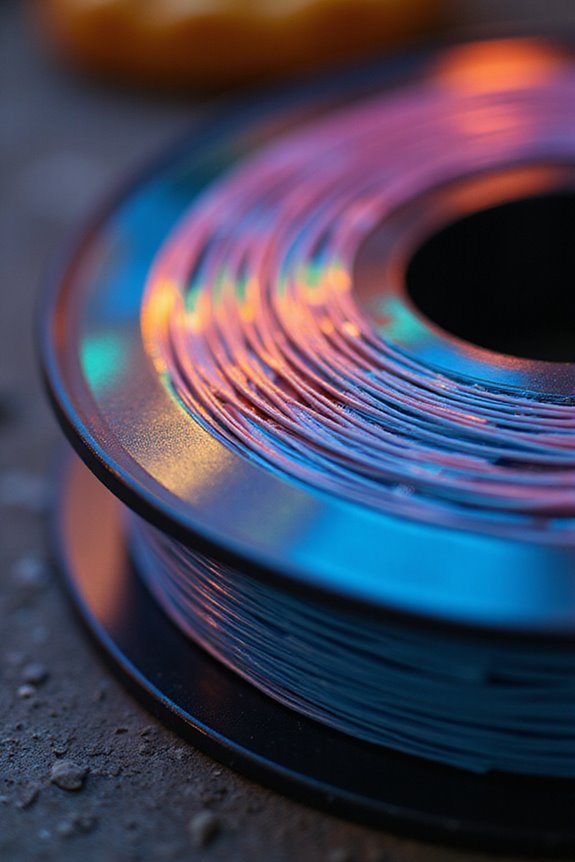

When picking a 3D printer filament type, we should consider the material properties and our project needs. For instance, PLA is great for beginners due to its easy printability and biodegradability. ABS suits functional parts requiring heat resistance, while PETG offers strength and versatility for medium-impact items. Don’t forget TPU for flexible applications like phone cases. Each filament has unique requirements and suitability, and understanding these can greatly enhance our project outcomes. There’s more to explore on choosing the right filament.

Key Takeaways

- Assess project requirements; choose a filament based on the final product’s strength, flexibility, and environmental exposure.

- Consider ease of printing; start with PLA for beginners due to its low temperature requirements and minimal warping.

- Evaluate the health and safety implications; select filaments that emit fewer VOCs and ensure proper ventilation during use.

- Prioritize eco-friendly options; recycled filaments significantly reduce environmental impact and align with sustainability practices.

- Understand material properties; each filament type, like TPU for flexibility or ABS for durability, serves different application needs.

Understanding 3D Printer Filaments

When it comes to 3D printing, the filament we choose greatly impacts our results. Understanding filament types helps us determine which material suits our specific project needs. For example, ABS is durable and heat-resistant, making it perfect for parts needing impact resistance, while PETG balances durability with ease of use. If flexibility is a priority, we might opt for TPU/TPE, though it requires slower print speeds for best results. Utilizing varied printing techniques can enhance our outcomes, as some materials like Nylon are challenging but offer exceptional strength. Ultimately, selecting the right filament leads to successful projects, whether we’re prototyping with PLA or crafting industrial components with continuous fiber filaments. Understanding these options guarantees we’re well-prepared for any 3D printing adventure.

Overview of PLA Filament

Although we often think of 3D printing as a technical endeavor, the materials we select, like PLA filament, play a pivotal role in achieving high-quality outcomes. PLA characteristics, derived from renewable sources like cornstarch, highlight its sustainability and eco-friendly nature. It’s favored for PLA printing due to its low extrusion temperature, making it beginner-friendly with minimal warping.

Its versatility shines in applications ranging from educational models to artistic sculptures. Praised for good layer adhesion and a pleasing finish, PLA advantages include its cost-effectiveness and availability in various colors and PLA variants. However, note its solubility in specific solvents and that while it’s biodegradable, it’s best suited for environments where sustainability is a priority. Additionally, high-quality PLA maintains a tolerance of +/- 0.02mm, which significantly affects printing performance.

Exploring ABS Filament

As we plunge into the world of 3D printing materials, it’s essential to contemplate ABS filament for its unique properties and capabilities. Known for its moderate strength and flexibility, ABS, or Acrylonitrile Butadiene Styrene, is particularly well-suited for functional applications like tool handles and automotive components. Its heat resistance makes it preferable for items exposed to higher temperatures, such as electrical enclosures. With recent advancements in filament innovations, we can create robust prototypes and consumer products, including phone cases and toys. However, we must be aware of its tendency to warp, necessitating a heated bed and enclosed build chamber. Overall, ABS filament opens numerous doors in diverse industries, showcasing its versatility and reliability.

Benefits of PETG Filament

Building on our exploration of ABS filament, let’s now consider the benefits of PETG filament, which stands as a strong alternative in the world of 3D printing materials. One of the standout features of PETG is its excellent layer adhesion, ensuring robust and smooth prints with minimal imperfections. This makes it an ideal choice for functional parts and prototypes that require durability, such as outdoor items or kitchenware.

Moreover, PETG showcases impressive chemical resistance, allowing it to withstand acidic and alkali environments without degradation. It also boasts low warping and reduced shrinkage, minimizing print failures. Whether you’re a beginner or an experienced printer, PETG simplifies the printing process, enabling high-quality results with every project.

Characteristics of TPU/TPE Filaments

When it comes to flexible 3D printing materials, TPU and TPE stand out for their unique characteristics, making them suitable for a range of applications. TPE properties offer exceptional flexibility, allowing for the creation of soft, stretchable parts. However, TPU advantages shine through with its impressive durability, higher tensile strength, and excellent resistance to chemicals and UV rays, which makes it ideal for demanding applications outdoors.

TPU printability tends to be user-friendly, especially when utilizing a direct drive extruder. Conversely, TPE processing can be more complex, often requiring fine-tuning to improve adhesion. Ultimately, the choice between TPU and TPE depends on the specific requirements of your project, including desired flexibility, durability, and environmental resistance.

Specialty Filaments and Their Uses

Specialty filaments expand our 3D printing horizons far beyond the typical materials like PLA and ABS. For instance, polycarbonate applications benefit from its incredible strength and temperature resistance, ideal for drone components. Similarly, BendLay features offer a flexible, translucent option that’s perfect for food-safe containers. Carbon fiber benefits include enhanced rigidity without added weight, making it perfect for structural parts in high-performance engineering like automotive applications. Plus, nylon advantages, such as excellent toughness and impact resistance, allow for durable gears and fittings. Finally, for complex designs, support filament uses such as PVA and HIPS guarantee that intricate geometries come out flawlessly, being easy to remove and enhancing our creative potential.

Comparing Mechanical and Physical Properties

How do we choose the right filament based on mechanical and physical properties? Understanding tensile strength, heat resistance, and impact durability is essential for effective material selection. For instance, ABS offers high tensile strength but can be brittle under stress, while PETG provides better elasticity. When we consider hardness comparison, NylonG excels in impact resistance, ideal for rugged applications. Flexibility range varies too, as TPU and TPE are excellent for bendable parts, though they lack strength. In addition, environmental degradation plays a significant role; PETG resists UV light better than ABS, prolonging its lifespan outdoors. Applying these insights helps determine the ideal filament for specific needs, whether rigid prototypes or durable, weather-resistant components.

Printing Requirements for Different Filaments

Understanding the mechanical and physical properties of different filaments is only the first step in the printing process. We need to pay attention to temperature settings—PLA prints around 180-220°C, while ABS requires 220-250°C. Equally important are bed surfaces; for instance, PLA adheres well to blue tape, whereas ABS benefits from heated beds. Print speeds and cooling requirements vary too; for example, TPU needs slower speeds due to its flexibility. Proper filament handling and storage conditions, particularly for hygroscopic materials like Nylon, are essential to prevent moisture-related extrusion issues. Utilizing effective adhesion techniques, like PVA glue for nylon, also aids in achieving quality prints. Let’s optimize our setups for each filament type to enhance our printing experience!

Application Suitability for Various Projects

Which filament is best for our specific projects? Our choice hinges on project requirements and material selection. For prototypes and decorative items, PLA is a top pick due to its ease of printing and biodegradable nature. If we need durable, functional parts, ABS is ideal thanks to its strength and heat resistance, although post-processing is necessary.

For projects needing flexibility, TPU/TPE excels, especially in applications like phone cases. PETG strikes a balance, being suitable for watertight containers and moderate-impact items. Finally, if we require high tensile strength, nylon is great for mechanical components, though it demands careful handling. By understanding these attributes, we can choose the best filament for our needs.

Environmental and Safety Considerations

When selecting a filament, it’s important to contemplate not just the project requirements but also the environmental and safety implications of our choices. By considering sustainability practices, we can choose filaments that have a lower environmental impact. For instance, recycled filaments greatly reduce CO2 emissions—over 50% compared to virgin materials. Additionally, some filaments emit fewer volatile organic compounds (VOCs), enhancing air quality in our workspaces. It’s essential to prioritize well-ventilated printing environments to protect our health while operating 3D printers. Choosing eco-friendly alternatives not only helps minimize plastic waste but also aligns with our commitment to responsible practices. As we innovate, let’s actively shape a more sustainable future in 3D printing.

Frequently Asked Questions

Can I Mix Different Filament Types While Printing?

Yes, we can mix different filament types while printing, but we need to take into account filament compatibility and the mixing properties. Some combinations work well, while others might lead to adhesion issues and print failures.

How Do I Store 3D Printer Filaments Properly?

When storing 3D printer filaments, we should prioritize humidity control by using airtight containers. This way, we can prevent moisture damage and guarantee our filaments remain in great condition for future printing projects.

What Is the Shelf Life of 3D Printer Filaments?

Imagine discovering our PLA filament warped after six months. We learned that filament degradation factors like humidity are essential. To avoid this, we keep our materials under ideal storage conditions, ensuring they last up to two years.

Do Filaments Have Different Color Options Available?

Yes, we’ve noticed a wide color variety in filaments, allowing for excellent filament customization. Whether we prefer bold hues or soft pastels, there’s always a perfect shade for our 3D printing projects.

How Do I Troubleshoot Common Filament Printing Issues?

When it comes to our 3D printing adventures, if we encounter a clogged nozzle or inconsistent extrusion, we can always check temperatures, confirm filament’s dry, and calibrate our printer for smoother operations and vibrant results.